With the increase of demand for environmental protection, many small pellet mill manufacturers have appeared. How to make your own pellets for home use? What kind of small pellet mills should you choose? If you’re thinking of making your own pellets you’ve come to the right place!

How to choose the most suitable small pellet mill?

Small pellet mill, also called flat die pellet mill, is usually used by small scale pellet plant, small farms or home use. According to different power, small pellet mill can be classified into 4 types: electric pellet mill, diesel pellet mill, PTO pellet mill and gasoline pellet mill. Depending on different materials, we have biomass pellet mill, wood pellet mill, feed pellet mill, etc.

Use a small wood pellet mill in diesel pellet mill or electric pellet mill, you can make feed pellets or bedding for animals. Stop paying the high energy bills. Your materials should be free, so make as much as you like and stay warm and comfortable without the energy costs free heat.

Many different materials like sawdust, wood chips, cardboard, newspaper, leaves, grass, soy plant, corn stalk, switch grass, hay, alfalfa, manure could be used. If you have enough such materials at home, you can choose the most suitable small pellet mills for your own use.

How to make pellets for home use with small pellet mill?

Now you have your pellet mill, then how to make pellets with your pellet mill? Simple 7 steps tell you how to make pellets by yourself.

Step 1

Gather the wood or other materials be used and reduce the size of wood pieces with crushing machine until the pieces are no longer than 1 inch (2.5cm). Hammer mill should be used to reduce the size of wood and get the pieces as small as possible without turning it into sawdust.

Step 2

Dry the pieces of material. The content moisture should be 10 to 20 percent. There are two methods drying materials, leave the wood in the sun to dry naturally, or place the materials in an industrial slow heating oven until it is dried to the suitable level.

Step 3

Pouring the material into a batch mixer and ensure all the material become uniform and consistent in density, moisture and size.

Step 4

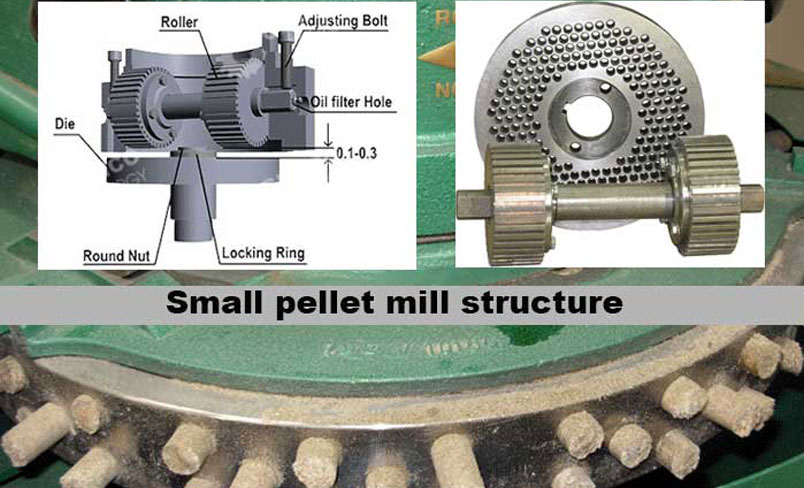

Produce the pellets using your small pellet mill. A pellet mill contain a die and roller, the die is a metal piece with holes drilled through it. The roller goes across the die and presses the wood through the holes into pieces the size of finished pellets.

Step 5

Screen out the pellets which are not formed properly. During the pressing process, some pieces will fall apart or breaking so that we should separate the improperly formed pieces.

Step 6

Cool the pellets thoroughly. When the pellets come out of the pellet mill, they would be hot and moist. Therefore, the dryer is necessarily.

Step 7

Packing and store the pellets. In order to better transportation, the packing bags should not be too big. What’s more, the pellets need to be stored in a dry place in case of moist.