Rotary Drum Dryer

The rotary dryer is a kind of industrial dryer used to reduce the moisture content of the material. It is commonly used in the mineral industry for drying sands, limestone, stones and soil, ores, fertilizers, wood chips, coal, filter cakes, sewage sludge, etc.

What’s more, it is also an indispensable equipment in biomass pellet plant, especially for wood and sawdust that have a high moisture level. We know that if the material is too wet, the pellets made out will be easy to break. Therefore, the rotary dryer is necessary to keep the materials’ moisture between 12% and 18%.

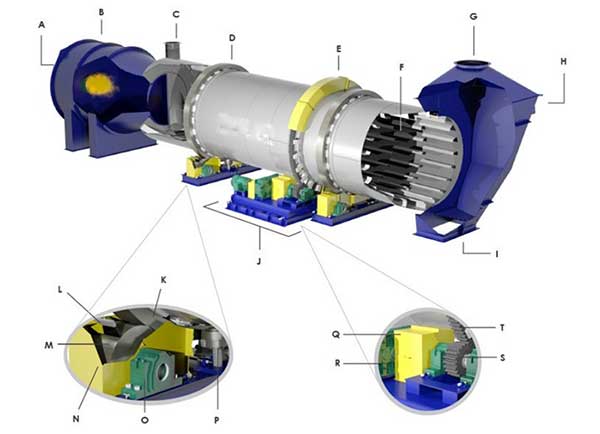

The dryer machine we use is rotary drum dryer, which consists of shell, lifting flight, drive assembly, support system and seal.

A – Burner B – Combustion Chamber C – Raw Material Feed Chute

D – Riding Ring/Tire E – Gear/Sprocket Guard F – Flights

G – Exhaust Handling System H – Discharge Breeching I – Product Discharge

J – Drive Assembly K – Drum Shell Riding Ring L – Graphite Block Lubrication Assembly

M – Trunnion Wheel N – Trunnion Guard O – Pillow Block Bearing

P – Thrust Roller Assembly Q – Coupling Guard R – Gear Reducer

S – Pinion Gear T – Girth Gear